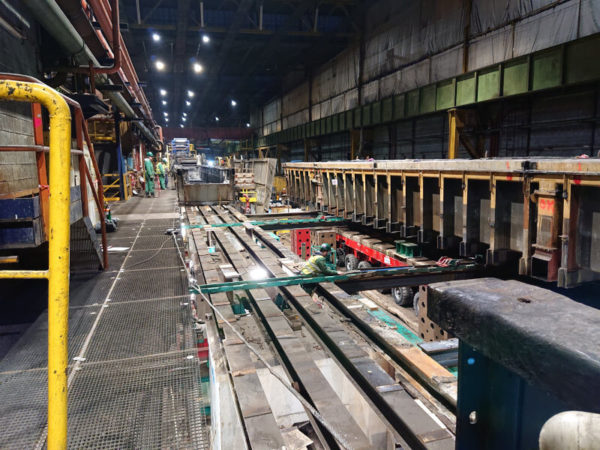

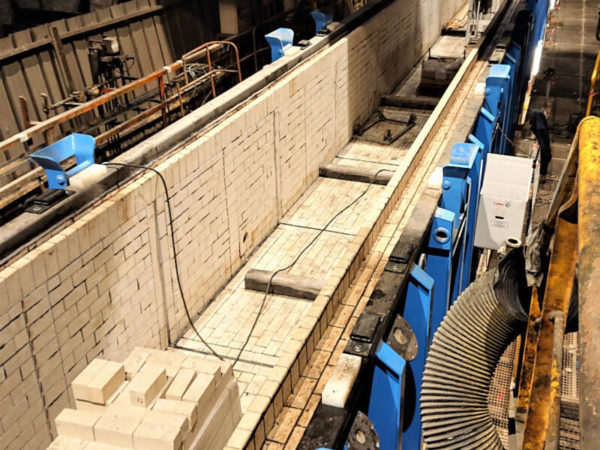

Pickling tanks

Kalker Garay supplied and installes 2 pickling tanks for the world biggest steel producer. The carbone steel tanks are protected with ebonite lining that we produce in our facilities and with 3 layers of antiacid bricks for a total thickness of 300mm. The total length of the tanks is 51m, the weight is 280 tons.

The rubber lining and vulcanization have been made in our workshop, assembling of tanks and brick lining were done at customer site. To reduce the duration of production line stop for tanks replacement, all the heavy handlings were operated by jacking and skidding. These works that requires special skills and specific equipment have been realized by ou partner the company Scales under our supervision.

This project follows the replacement in 2016 of the first 2 pickling tanks. Our teams are particularly proud to have participated in the replacement of all the pickling tanks on this line.

Corrosion protection is provided by a bromobutyl elastomer coating. The grade of coating used meets a number of specific requirements: excellent resistance to chemical products and a high resistance to diffusion.

Corrosion protection is provided by a bromobutyl elastomer coating. The grade of coating used meets a number of specific requirements: excellent resistance to chemical products and a high resistance to diffusion.

Application of a hard rubber coating which has been specifically developed for use in water treatment facilities or filtration units which use membranes (desalination of sea water, chlorine electrolysis).

Application of a hard rubber coating which has been specifically developed for use in water treatment facilities or filtration units which use membranes (desalination of sea water, chlorine electrolysis).